Sustainable Substrates

Finding New Potting Materials for Ornamental Nursery Crop Production

The long-term goal of this project, funded by the Floriculture and Nursery Research Initiative with guidance from the American Nursery and Landscape Association Horticultural Research Institute, is to identify and develop regional and sustainable sources of horticultural substrates for the nursery industry.

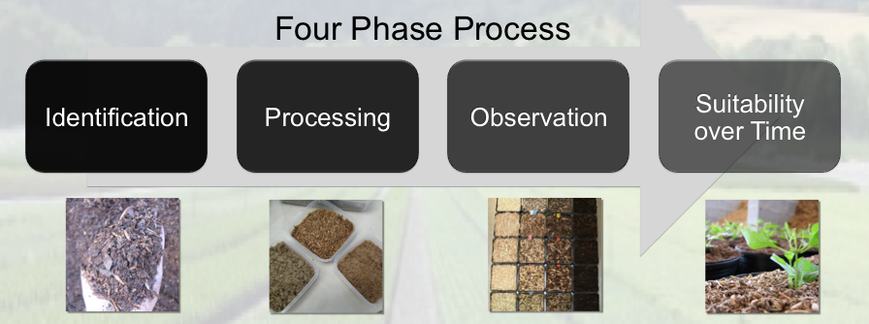

Our team’s approach for developing new substrates is a four-phase process. First, materials are identified that might be used as substrates on a regional basis in each of our respective regions. Potential of using these materials on a cross-regional basis is also discussed amongst our group (we are currently exploring the idea of using bamboo biomass as a substrate in all of our regions). Some materials may have a limited range of utility (for example invasive red cedar in the Kansas region or reed-sedge peat in the upper Midwest region).

Our team’s approach for developing new substrates is a four-phase process. First, materials are identified that might be used as substrates on a regional basis in each of our respective regions. Potential of using these materials on a cross-regional basis is also discussed amongst our group (we are currently exploring the idea of using bamboo biomass as a substrate in all of our regions). Some materials may have a limited range of utility (for example invasive red cedar in the Kansas region or reed-sedge peat in the upper Midwest region).

The second phase of the investigation involves taking the material from its parent form and processing it into a usable substrate.

The third phase of the process involves observation of the materials in the container. Our current process is to use fast-growing herbaceous crops to quickly ascertain how the substrates interact with common fertilizers and amendments typically used by nursery producers.

The fourth phase is to determine the suitability of these materials over a period of 4 to 12 months, which is the typical production cycle for woody nursery crops. All materials evaluated to date have lower lignin content than pine bark. Lignin is a complex polymer that binds to cellulose fibers to strengthen and harden plant cell walls. It is thought that the lesser the lignin content, the less stable the material will be in the container environment. Thus changes in substrate physical properties over time is the primary concern during this phase of evaluation.

Most of this research has been under the first three phases.

Thus far, our team has been working with the following plant biomass sources: Switchgrass (Panicum virgatum), Willow (Salix spp.), Corn (Zea mays) stover, Giant Miscanthus (Miscanthus ×giganteus), Poplar (Populus spp.), Bamboo (Phyllostachys spp.), and Eastern Redcedar (Juniperus virginiana).

All of the above listed materials have higher pH than Pine or Douglas fir bark. Amendment with peat moss or compost at rates typical of nursery producers (varies by region) lowers pH in alternative substrates to a more moderate level (6.0 to 6.5).

We have found that materials processed through a hammermill equipped with a 3/8-in screen produces substrates with particle size distribution similar to bark substrates currently used. Despite similarities in particle size distribution, alternative materials tend to hold less water and have greater air space than pine bark. Amendment with sphagnum peat moss and compost decreases air space and increases water holding capacity to levels considered more ideal, and to levels similar to pine bark.

We are also studying nitrogen (N) dynamics in the alternative substrates. One of the initial concerns with all the aforementioned alternative substrates was N immobilization. As these substrates are probably more easily decomposed than pine or Douglas fir bark, they are also more likely to immobilize N to aid in the decomposition process. We have observed slow initial growth of some plants in alternative substrates compared to pine bark, however, after 6 to 8 weeks plants in alternative substrates had ‘caught up’ and outperform those in pine bark. We attribute this to temporary immobilization and subsequent release of N in alternative substrate materials. To eliminate the initial stunting of crops in alternative substrates, we are evaluating fertilizer application techniques that would turn this phenomena from a disadvantage to an advantage.

Our immediate goal now is to identify two or three materials with the greatest potential for use in the nursery industry, and focus our efforts on those materials to better understand how they react in the vast and complex environments typical of nurseries throughout North America.

The third phase of the process involves observation of the materials in the container. Our current process is to use fast-growing herbaceous crops to quickly ascertain how the substrates interact with common fertilizers and amendments typically used by nursery producers.

The fourth phase is to determine the suitability of these materials over a period of 4 to 12 months, which is the typical production cycle for woody nursery crops. All materials evaluated to date have lower lignin content than pine bark. Lignin is a complex polymer that binds to cellulose fibers to strengthen and harden plant cell walls. It is thought that the lesser the lignin content, the less stable the material will be in the container environment. Thus changes in substrate physical properties over time is the primary concern during this phase of evaluation.

Most of this research has been under the first three phases.

Thus far, our team has been working with the following plant biomass sources: Switchgrass (Panicum virgatum), Willow (Salix spp.), Corn (Zea mays) stover, Giant Miscanthus (Miscanthus ×giganteus), Poplar (Populus spp.), Bamboo (Phyllostachys spp.), and Eastern Redcedar (Juniperus virginiana).

All of the above listed materials have higher pH than Pine or Douglas fir bark. Amendment with peat moss or compost at rates typical of nursery producers (varies by region) lowers pH in alternative substrates to a more moderate level (6.0 to 6.5).

We have found that materials processed through a hammermill equipped with a 3/8-in screen produces substrates with particle size distribution similar to bark substrates currently used. Despite similarities in particle size distribution, alternative materials tend to hold less water and have greater air space than pine bark. Amendment with sphagnum peat moss and compost decreases air space and increases water holding capacity to levels considered more ideal, and to levels similar to pine bark.

We are also studying nitrogen (N) dynamics in the alternative substrates. One of the initial concerns with all the aforementioned alternative substrates was N immobilization. As these substrates are probably more easily decomposed than pine or Douglas fir bark, they are also more likely to immobilize N to aid in the decomposition process. We have observed slow initial growth of some plants in alternative substrates compared to pine bark, however, after 6 to 8 weeks plants in alternative substrates had ‘caught up’ and outperform those in pine bark. We attribute this to temporary immobilization and subsequent release of N in alternative substrate materials. To eliminate the initial stunting of crops in alternative substrates, we are evaluating fertilizer application techniques that would turn this phenomena from a disadvantage to an advantage.

Our immediate goal now is to identify two or three materials with the greatest potential for use in the nursery industry, and focus our efforts on those materials to better understand how they react in the vast and complex environments typical of nurseries throughout North America.